- Home

- Equipment

Refine by

Custom Conveyor Environmental Equipment & Supplies

5 equipment items found

Manufactured by:Custom Conveyor & Equipment Corporation based inCedar Rapids, IOWA (USA)

This machine combines lineshaft powered rollers, a ballscrew driven linear rail motion, and a set of timing belt driven crowder arms to recieve a 500lb package in vertical orientation, rotate it to horizontal orientation, then feed it out on the exact same centerline that it came in on. ...

Manufactured by:Custom Conveyor & Equipment Corporation based inCedar Rapids, IOWA (USA)

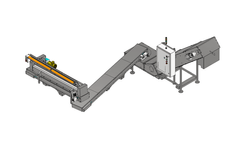

This single breaker cullet handling system is designed to fit in tight workspaces and offers turnkey controls. The system requires a 480/60/3 20A mains power connection to the control panel. It is specifically engineered for above-floor installation and can be fully customized to meet specific processing needs. Suitable for the handling of flat glass and plate glass, this system ensures efficient ...

Manufactured by:Custom Conveyor & Equipment Corporation based inCedar Rapids, IOWA (USA)

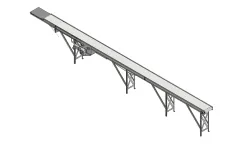

This comprehensive below grade cullet handling system integrates eight glass breakers across four breakout tables into a central cullet collection area for loading waste glass into a tractor trailer. The system is managed by an interconnected control system that monitors breaker torque, belt motion, and trailer fill levels. Customization options are available to adapt the system to specific ...

Manufactured by:Custom Conveyor & Equipment Corporation based inCedar Rapids, IOWA (USA)

This 28-foot long stainless steel modular belt conveyor is designed specifically for sanitary food processing environments, particularly protein processing facilities. It features a center drive mechanism and a flip-up gate with an accumulation tray at the end, providing efficiency and ease of use. Tailored for optimal sanitation, the conveyor meets rigorous industry standards, making it suitable ...

Manufactured by:Custom Conveyor & Equipment Corporation based inCedar Rapids, IOWA (USA)

This conveyor is engineered to seamlessly integrate with existing metal detection systems in new locations, catering specifically to food production environments. The toolless UHMW center section combined with a modular belt design ensures that the conveyor can be easily sanitized during washdown procedures, meeting strict sanitary requirements. Customized solutions can be fully tailored to meet ...